World's first designer jaw built from titanium using additive manufacturing

3 February 2012

Leuven, Belgium. Belgian company LayerWise has built a total lower jaw implant from titanium using its additive manufacturing (AM) system.

The jaw was built to treat a senior patient’s progressive osteomyelitis of almost the entire lower jawbone. Medical specialists and surgeons opted for such a complete patient-specific jaw implant — a world first — to replace the existing bone.

To make the jaw implant a high-precision laser selectively heats a layer of metal powder to quickly and fully melt to properly attach to the previous layer without glue or binder liquid. Layers are built successively to produce the complex shape of the lower jaw implant structure.

AM is used to print functional implant shapes that otherwise require multiple metalworking steps or even cannot be produced any other way. The revolutionary patient-specific implant has been developed and produced under supervision of Prof. Dr. Jules Poukens, in collaboration with specialized industrial and academic parties in Belgium and The Netherlands .

AM technology specialists at LayerWise printed the complex implant design incorporating articulated joints and dedicated features. The reconstruction — post-processed with dental suprastructure provisions, polished joint surfaces and a bioceramic coating — has been implanted successfully. It has restored the patient’s facial aesthetics and allowed her to regain her speech within hours.

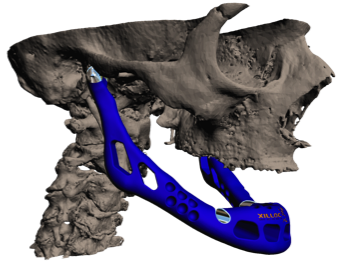

Left: The titanium jaw manufactured by additive

manufacturing

Right: Computer imaging of the jaw fitted to the

skull of the patient

Dr. ir. Peter Mercelis, Managing Director of LayerWise said, “Besides a successful track record in industrial sectors, metal AM is gaining importance in medical implantology. AM’s freedom of shape allows the most complex freeform geometries to be produced as a single part prior to surgery. As illustrated by the lower jaw reconstruction, patient-specific implants can potentially be applied on a much wider scale than transplantation of human bone structures and soft tissues. The use of such implants yield excellent form and function, speeds up surgery and patient recovery, and reduces the risk for medical complications.”

Surgeons placing the jaw in the patient

Prof. Dr. Jules Poukens of the University Hasselt said, “The new treatment method is a world premiere because it concerns the first patient-specific implant in replacement of the entire lower jaw. The implant integrates multiple functions, including dimples increasing the surface area, cavities promoting muscle attachment, and sleeves to lead mandible nerves.

"Furthermore, the mandible implant is equipped to directly insert dental bar and/or bridge implant suprastructures at a later stage. I led the team of surgeons who implanted the AM-produced structure during a surgery of less than four hours at the Orbis Medisch Centrum in Sittard-Geleen. Shortly after waking up from the anaesthetics the patient spoke a few words, and the day after the patient was able to speak and swallow normally again.”

About the project

The new method has been developed by the Biomed research group of the University Hasselt (Belgium) in collaboration with engineers from the Xios Hogeschool (Belgium), Xilloc Medical BV (NL) and University Leuven and maxillofacial surgeons from the Orbis Medisch Centrum Sittard-Geleen (NL). LayerWise NV (Belgium) produced the implant structure, which was coated with a bioceramic coating by Cam Bioceramics BV (NL).